There's no use beating around the bush. Determining the right sprinkler system is one of your most critical responsibilities when working with warehouse space. According to the National Fire Protection Association (NFPA), on average, there are 1,410 warehouse fires per year. When we break this down, that means 3 to 4 warehouse fires per day. So, warehouse fires happen-it's up to you to decide how prepared you want to be.

Sprinkler systems are your safeguard for your employees and property against a catastrophic warehouse fire. However, what's the right system? That’s a whole other story. There are many factors to consider, including the size of your warehouse and the type of materials stored inside. So read on the considerations you should know that will direct you to the right system.

What Commodity are You Storing?

Depending on your inventory (and the way you store it), your sprinkler demands will highly vary. To determine the proper system, you need to start with the class of commodity you’re working with.

Not only is classifying your commodity an expensive mistake, but it is also critically dangerous and will leave you liable to death, emergencies, steep fines, and career-ending lawsuits.

|

Class I Commodities |

This section is qualified by its lack of combustibility. The products generally pose a low risk for fire hazard and according to the International Fire Code, stored on “wooden or non-expanded polyethylene solid deck pallets, in ordinary corrugated cartons with or without single-thickness dividers, or in ordinary paper wrappings without pallets.” |

|

Class II Commodities |

The next class typically contains Class I products, but the difference lies in the storage means. Commodities are bumped up to Class II if they are stored in “slatted wooden crates, solid wooden boxes, multiple-thickness paper board carton, or equivalent combustible packaging material with or without pallets. |

|

Class III Commodities |

This section includes higher-risk products made of wood, paper, natural fiber cloth, or limited plastics (5% or less by total weight or volume). |

|

Class IV Commodities |

This qualification also includes Class I, II, or III products that are stored in plastic packaging. It also includes Group A and B plastics (a little more about that below) and some other criteria. |

|

Class V Commodities |

Here is the unofficial classification for plastic products (which are further broken into categories depending on their level of associated flammability).

Group A plastics include most consumer items like toys or bottles. They have a burning rate far higher than ordinary combustibles as such they carry the highest hazard.

Group B are generally softer plastics and not quite as flammable as Group A. Group C items are more difficult to ignite than the prior classifications, but once they begin to burn, are dangerously combustible. |

Types of Sprinkler Systems

Depending on your commodity type, storage behavior, and warehouse specifications, your sprinkler demands will obviously vary. So, now we’ll jump into the different types of sprinkler systems and when they may be the right solution.

Wet Sprinklers

The most common type of sprinkler system is the wet pipe system. This system is exactly what it sounds like-pipes are filled with water and ready to use at a moment's notice. When the sprinkler heads are triggered by heat, water flows through the pipes and out of the heads, dousing the fire in its tracks.

Wet pipes function with glass bulbs that break when the temperature around that specific head becomes high enough to shatter the glass.

However, wet pipe systems can't be used in certain conditions, such as if materials that could be damaged by water are being stored. Additionally, if the temperature in your warehouse dips below freezing, the water in the pipes could freeze and cause the system to malfunction- or worse, burst! So, wet sprinklers are only observed in heated buildings or climates where warehouse temperature will not go below 40 degrees Fahrenheit.

ESFR Wet Sprinklers

ESFR, or Early Suppression Fast Response, sprinklers are a type of wet sprinkler that is designed for high-piled storage. These sprinklers are triggered at a lower temperature than standard wet sprinklers and discharge more water, making them ideal for suppressing fires in high-piled materials. ESFR sprinkler systems provide twice the amount of water than traditional wet sprinklers (60 gallons per minute), whereas conventional sprinkler heads unleash 25 to 30 gallons per minute.

Image Source: MillbrookFireProtection.com

Since it is a water-based sprinkler, the ESFR System is limited to installations at or above 40°F/4°C.

Quell Sprinklers

Quell sprinklers are a newer type of system that is becoming increasingly popular. Rather than using water, they use a high-pressure mist to extinguish fires. This mist consists of tiny water droplets that quickly cool the fire and prevent re-ignition. Quell sprinklers are ideal for warehouses storing sensitive materials that could be damaged.

Since no water is stored in the pipes, there is no risk of the pipes freezing and bursting in cold temperatures.

Image Source: firecontrolsprinklers.com

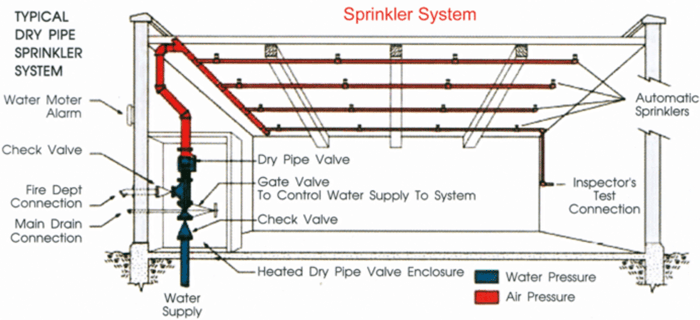

Dry Sprinklers

Dry sprinklers are a type of system that is most often used in warehouses where materials that could be damaged by water are stored.

In this type of system, the pipes are empty and only filled with pressurized air. When the sprinkler heads are triggered, the compressed air forces water out of the lines and onto the fire.

The main advantage of a dry sprinkler system is that there is no risk of water damage to stored materials. The drawback is that it requires more maintenance than other types of systems. Additionally, if the nitrogen generator fails, the system will not work. Also, there is a delay between sprinkler operation and water flow.

Image Source: Qrfs.com

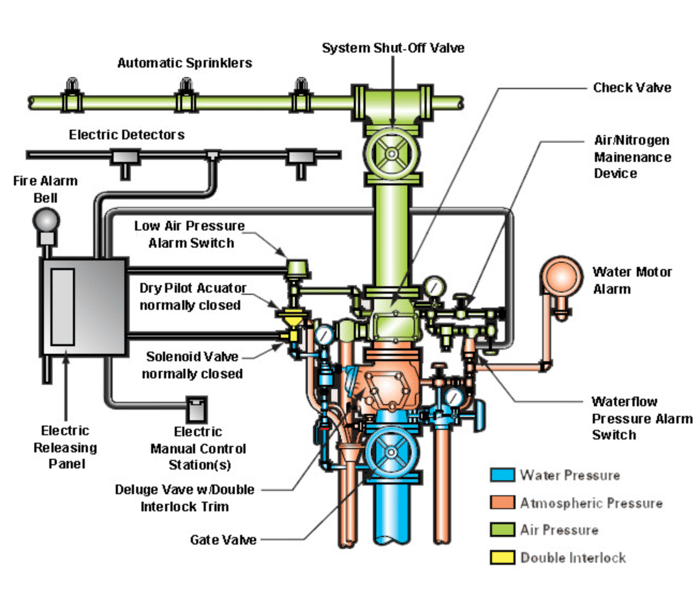

Pre-Action Sprinklers

Pre-action sprinklers are a type of system that combines the best of both wet and dry systems. In this type of system, the pipes are empty but pressurized with nitrogen. Water is withheld from the piping by an electronically operated valve.

When the sprinkler heads are triggered, the compressed air forces water out of the pipes and onto the fire.

The con of pre-action sprinklers is that they are more expensive to install than other systems. Additionally, it’s not uncommon for sprinkler heads to be falsely triggered.

When this happens, water damage can occur before the fire is extinguished.

Deluge Sprinklers

Deluge sprinklers are a system most often utilized in warehouses where high-hazard materials are stored. In this system, the pipes are empty but pressurized with nitrogen. It is connected to a water supply which, when activated by smoke or heat, triggers the sprinkler heads to open and force water onto the fire.

Deluge sprinklers are used to deploy a massive supply of water at once. They also are empowered to act fast since all the sprinkler heads open and release water.

The biggest advantage of deluge sprinklers is that they can quickly extinguish a fire. Additionally, since the system does not rely on stored water, there is no risk of the pipes freezing and bursting in cold temperatures.

The negative of deluge sprinklers is that they can cause a lot of water damage if the sprinkler heads are falsely triggered.

Image Source: Carolina Fire Protection

Foam Sprinklers

Foam sprinklers are a type of system that is most often used in warehouses where flammable liquids are stored. In this type of system, the pipes are filled with a foam solution that is designed to extinguish fires. When the sprinkler heads are triggered, the foam solution is forced out of the lines and onto the fire.

The biggest advantage of a foam sprinkler system is that it is very effective at extinguishing fires. Additionally, the foam solution prevents the fire from reigniting.

The most significant disadvantage of a foam sprinkler system is that it is more expensive to install and maintain than other types of systems. Additionally, the foam solution can become ineffective if the pipes are not properly maintained.

Determining the Right Sprinkler System

Warehouses that store commodities at risk for fires, such as Class III, and IV should consider implementing fast-acting sprinkler systems. For example, ESFR and quell systems would be good solutions. On the other hand, higher hazard threats should perhaps be pre-guarded with foam systems.

The key thing is to check your insurance. It will guide you to what system will give you the best level of protection and what you may be covered for.

If you want to learn more about how to cover all your bases when it comes to warehouse space, you don't need to do it alone. At iOptimize Realty®, we are Tenant Reps who can help you make critical commercial real estate decisions to benefit your company. Whether this means finding the right sprinkler system or negotiating with your landlord, you have a professional with 30+ years of market knowledge only representing tenants.

Want to learn more about creating the perfect warehouse environment? You'll want to read the Ultimate Warehouse Checklist.

Ready for solutions today? Talk to a Tenant Rep now.